If you want to reinforce your buckets for reliable heavy lifting, there are several approaches you can take to ensure their durability. Here are some suggestions:

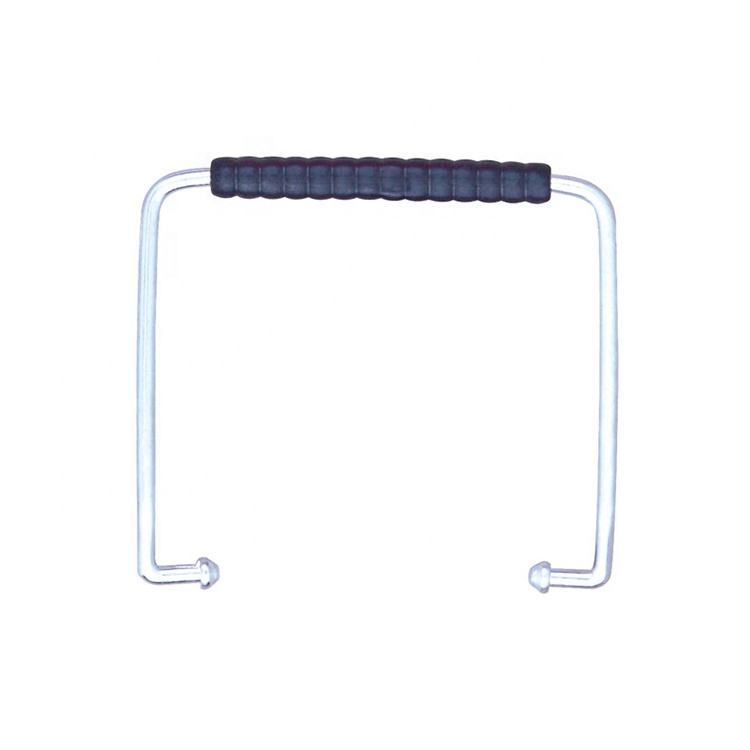

- Reinforced Handle Attachments: One of the critical stress points on a bucket is where the handle attaches to the body. Reinforcing this area can significantly increase the bucket’s overall strength. Manufacturers may use thicker or reinforced materials, such as metal or sturdy plastic, at the attachment points to prevent breakage or detachment.

- Double or Reinforced Walls: Another way to enhance the durability of a bucket is by incorporating double walls or reinforced sections. This design provides extra structural integrity and prevents the bucket from flexing or buckling under heavy loads. The additional layers can be made of thicker plastic or reinforced with internal supports.

- Thicker Bottom and Rim: The bottom and rim of a bucket are subjected to substantial stress during heavy lifting. Strengthening these areas can make a significant difference in the bucket’s overall durability. Opting for buckets with thicker bottoms and reinforced rims helps prevent cracking, warping, or splitting when carrying heavy loads or stacking multiple buckets.

- High-Quality Materials: Choosing buckets made from high-quality materials, such as durable plastics or metals, can greatly enhance their strength and longevity. Look for buckets that are specifically designed for heavy-duty applications and are known for their robust construction.

- Reinforced Ribs or Grid Patterns: Some buckets feature reinforced ribs or grid patterns on their exterior surfaces. These structural elements add strength and rigidity to the bucket, making it more resistant to deformation or collapsing under pressure.

- Impact Resistance: Consider buckets that are designed to withstand impacts and rough handling. These buckets are often made from impact-resistant materials that can absorb shocks without cracking or breaking. Reinforcements, such as corner guards or thicker sections, can also be incorporated to protect vulnerable areas from damage.

- Load Capacity Specifications: Pay attention to the manufacturer’s load capacity specifications for the bucket. Choosing a bucket that is rated for heavy loads ensures that it has been tested and designed to handle the weight you intend to lift. Exceeding the recommended weight limits can compromise the bucket’s structural integrity and increase the risk of failure.

By considering these factors and selecting buckets with reinforced features and high-quality construction, you can ensure that your buckets are well-equipped to handle reliable heavy lifting tasks. Always follow the manufacturer’s guidelines and use appropriate lifting techniques to prevent injury and maintain the longevity of your buckets.